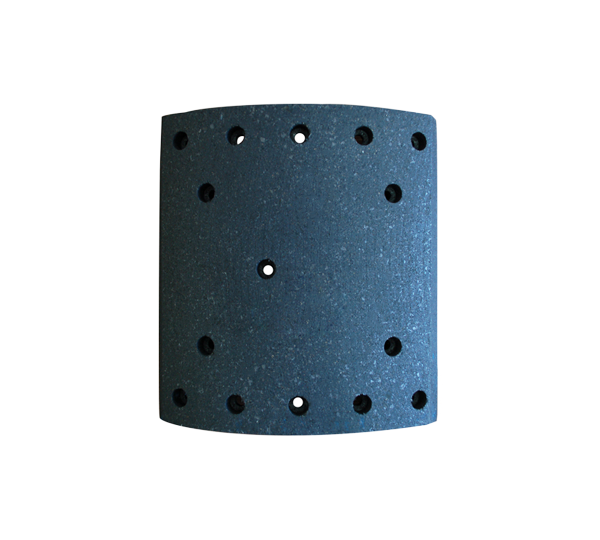

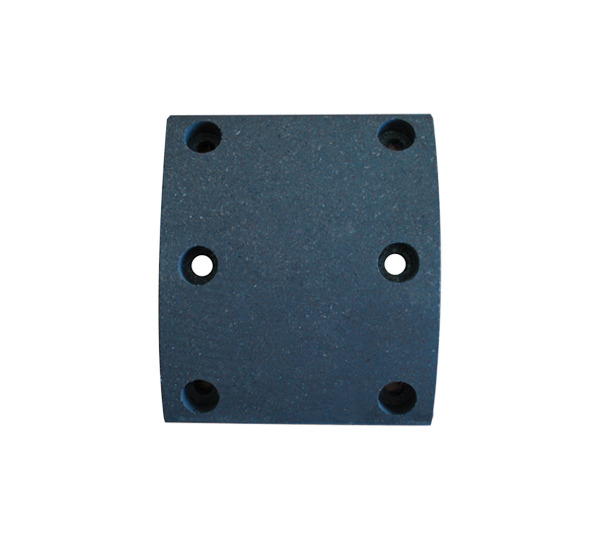

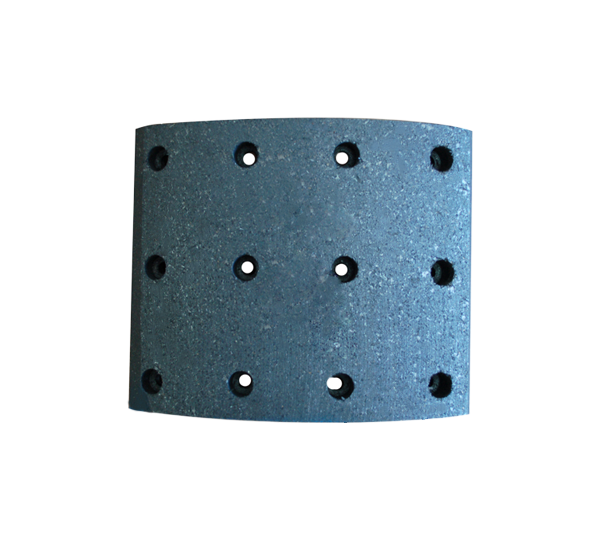

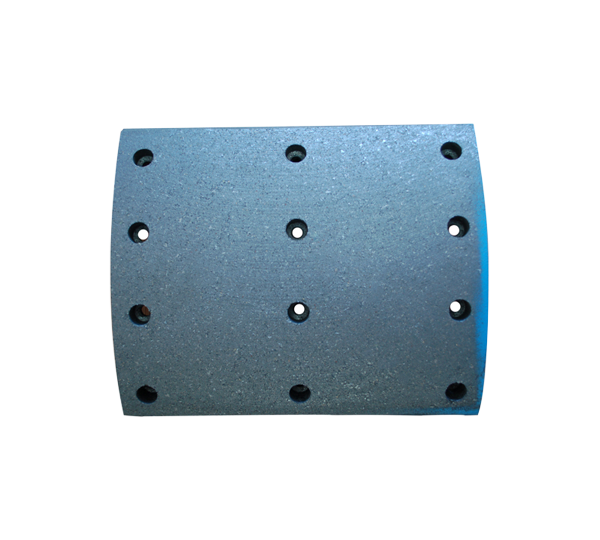

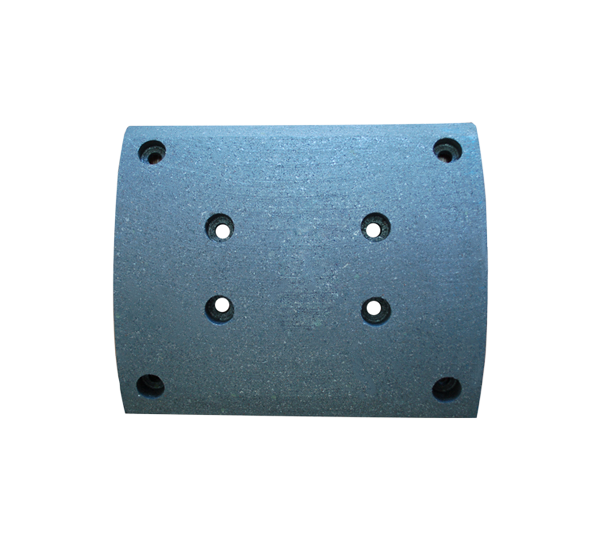

Choosing a good truck brake lining is important for long-term stopping power. There are different kinds of brake linings made from different materials. Choosing the right one can be tricky. You can contact the manufacturers to learn more about the specific products.

Brake linings must be durable and withstand a high amount of heat. They also must be resistant to wear. Most brake linings are formulated to match a specific application. In addition, they must be able to withstand the pressures involved in driving a heavy truck.

The NHTSA has a program for testing brake linings. It measures brake lining torque at pressures ranging from 20 psi to 80 psi. It has also expanded the testing program to include multiple axle loads.

The program uses three different test methods to quantify wear. It includes a nondestructive method to measure lining compressibility. It also includes an inertia dynamometer wear test. Both methods are time-consuming and expensive. However, they can be used for quality control.

Brake linings are made from a mixture of composite materials. This mix is then exposed to pressure and heat for a period of time. The pressure and heat can change the formulation of the brake lining. It can also alter the geometry of the brake system. This change can affect the wear response.

To measure the wear resistance of the lining, three different commercial truck brake lining materials were worn against gray cast iron. Wear debris was removed from each sample.

English

English 中文简体

中文简体