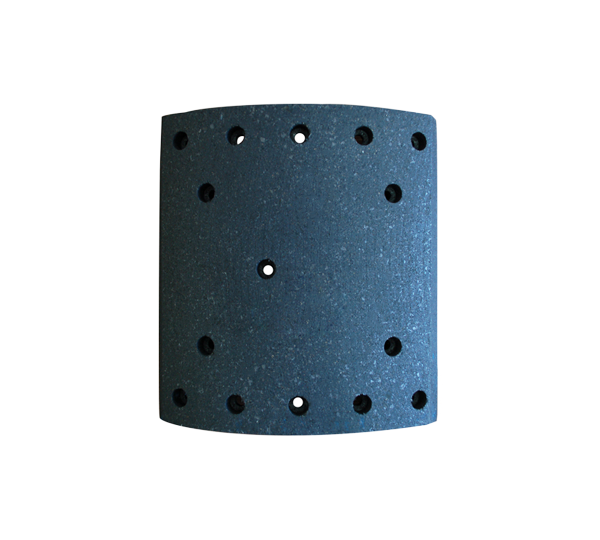

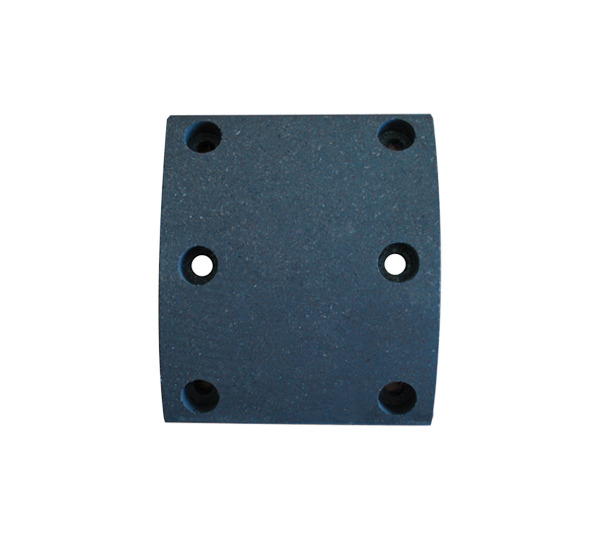

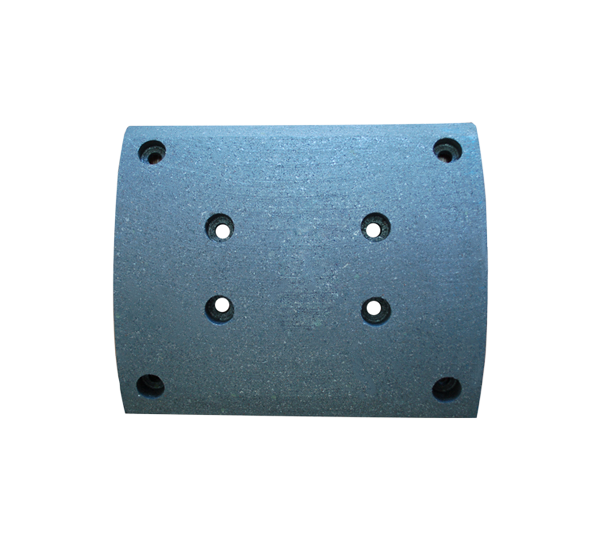

Non asbestos brake lining are typically made from various materials, such as organic compounds, aramid fibers, ceramics, and other composites. These materials are engineered to provide similar or improved braking performance while eliminating the health risks associated with asbestos.

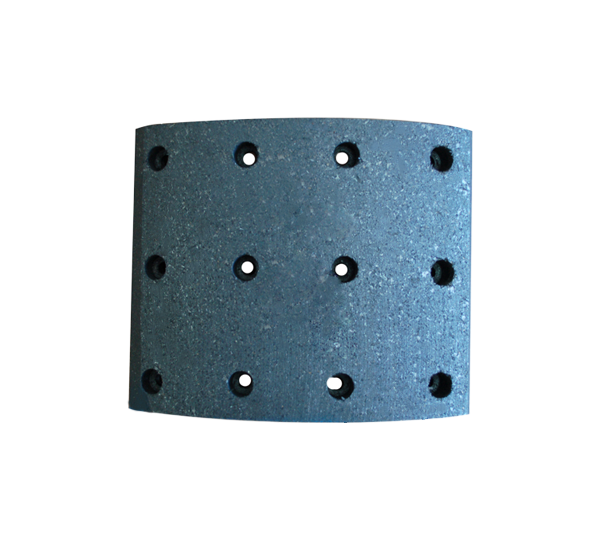

In terms of lifespan, non-asbestos brake linings can vary depending on the specific materials used, the driving conditions, and the driving style of the vehicle operator. Generally, non-asbestos brake linings can have comparable or even longer lifespans than traditional asbestos brake linings.

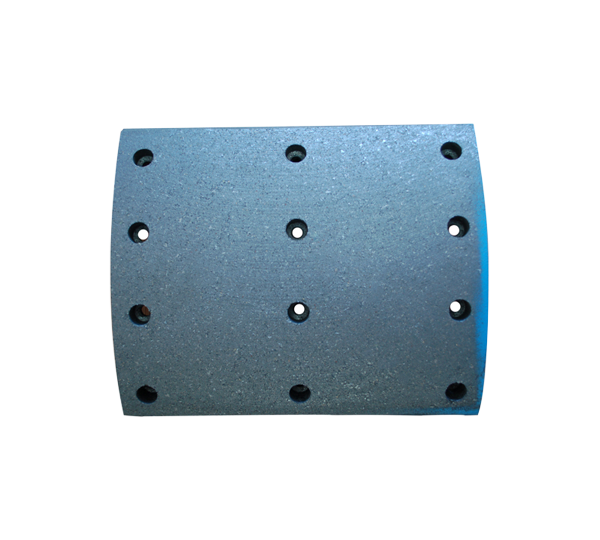

Factors that can influence the lifespan of brake linings include:

Driving Conditions: Frequent stop-and-go driving in city traffic or hilly terrain can lead to faster brake wear compared to highway driving with fewer stops.

Driving Habits: Aggressive driving, which involves frequent and hard braking, can wear down brake linings more quickly.

Brake Design: The type of braking system and brake components used can affect the wear rate of the brake linings.

Quality of Brake Linings: The quality and composition of the brake linings can vary among manufacturers, affecting their durability.

Maintenance: Regular brake inspections and proper maintenance, such as cleaning and lubrication, can extend the lifespan of brake linings.

It is important to follow the manufacturer's recommendations and guidelines for brake maintenance and replacement intervals to ensure optimal performance and safety.

PREV:What are the safety implications of using low-quality or improperly installed brake linings?

NEXT:How do non-asbestos brake linings compare to traditional asbestos-based linings in terms of performance?

NEXT:How do non-asbestos brake linings compare to traditional asbestos-based linings in terms of performance?

English

English 中文简体

中文简体