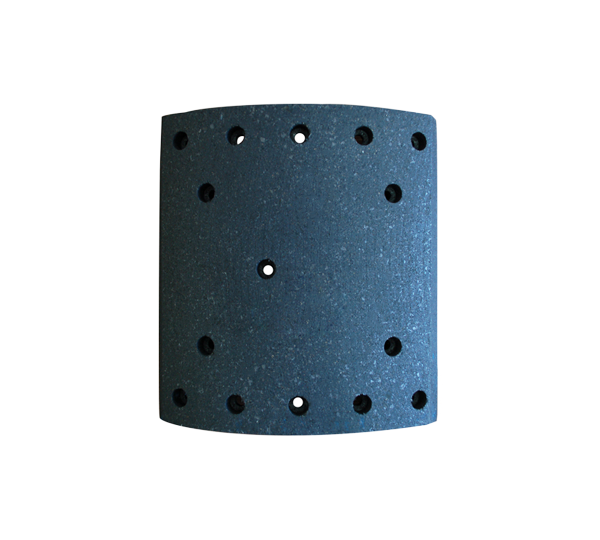

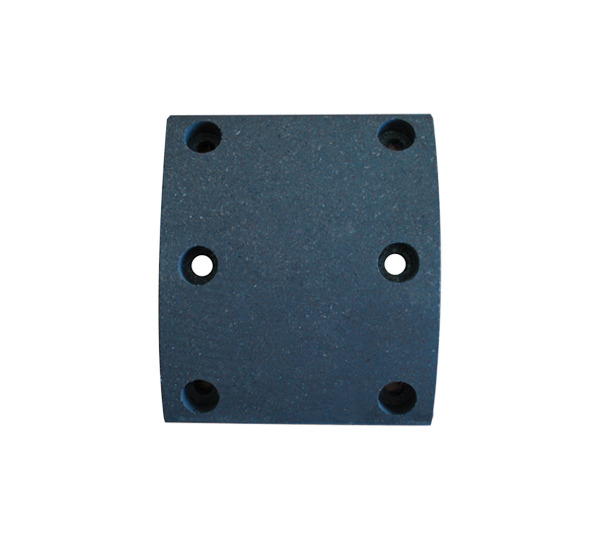

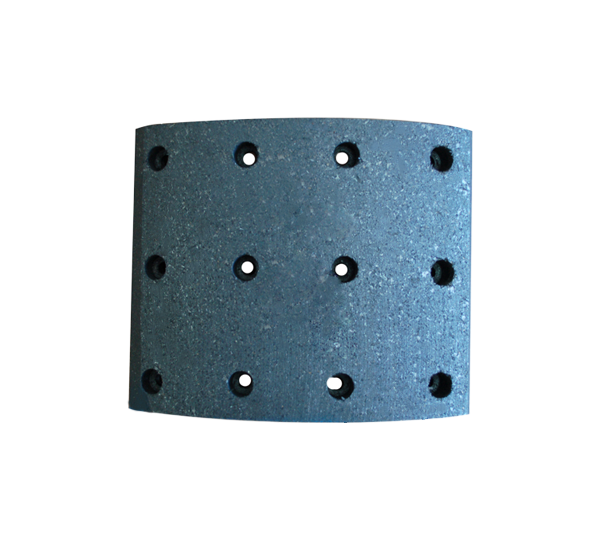

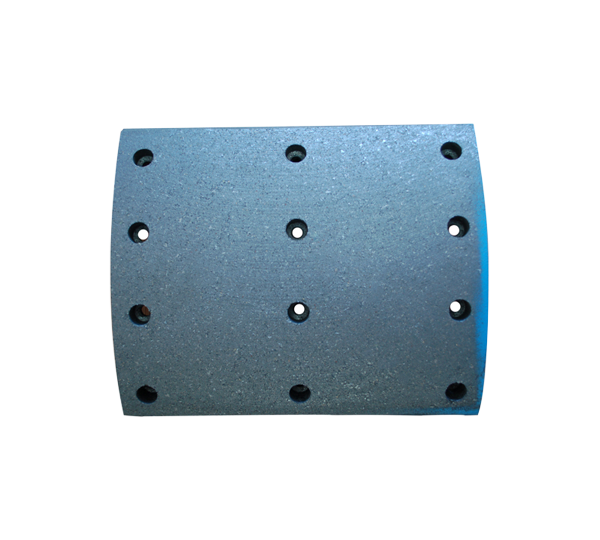

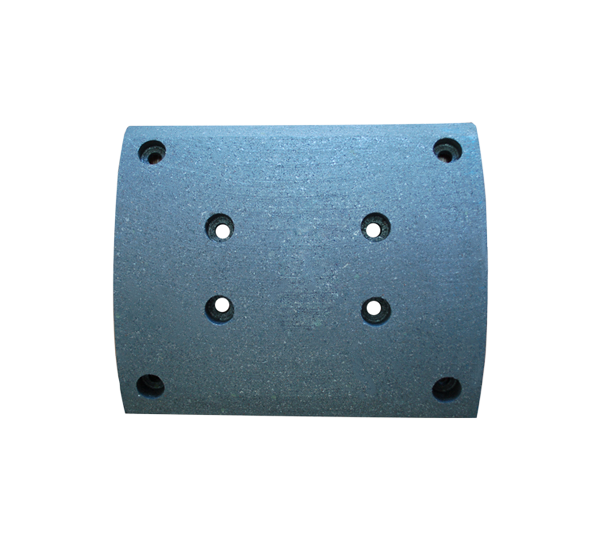

Non-asbestos brake linings are commonly used as a replacement for traditional asbestos-based brake linings, which are known to be hazardous to health due to the release of harmful dust particles during wear. Non-asbestos brake linings are made from a combination of synthetic and natural fibers, and are designed to provide safe and reliable braking performance in a wide range of applications.

Here are some applicable scenarios for non-asbestos brake linings:

Passenger Cars and Light Duty Vehicles: Non-asbestos brake linings are commonly used in passenger cars and light duty vehicles, as they provide excellent stopping power and wear resistance, while also being environmentally friendly and safe for the mechanics working on the vehicle.

Commercial Vehicles: Non-asbestos brake linings are also widely used in commercial vehicles such as trucks, buses, and trailers. They offer good durability and consistent braking performance, making them a popular choice for fleet operators.

Industrial Machinery: Non-asbestos brake linings are also used in industrial machinery such as cranes, hoists, and winches. These applications require strong and reliable braking performance, and non-asbestos brake linings provide the necessary stopping power while also being resistant to wear and tear.

Agricultural Equipment: Non-asbestos brake linings are also used in agricultural equipment such as tractors and combines. These applications require durable and reliable braking performance, as they often operate in harsh and challenging environments.

Overall, non-asbestos brake linings are a safe and reliable alternative to traditional asbestos-based brake linings, and are widely used in a variety of applications where strong and consistent braking performance is essential.

PREV:What problems will be encountered when using brake lining?

NEXT:How is the brake pad installed?

NEXT:How is the brake pad installed?

English

English 中文简体

中文简体