With normal braking intensity and frequency, the temperature of the brake pads is kept within 250°C, and the dragging makes the use temperature of the brake pads reach over 400°C, which is beyond the normal braking temperature range. Such a high temperature is generally only available in the laboratory. Under certain conditions, repeated high-intensity braking artificially set on the bench or dragging and grinding for a long time will only occur; a habitual explanation in this case is that the user uses it in bad road conditions. Is there any external easy? Fire caused it? We thought of the electrostatically sprayed paint powder on the brake pads, and tested it in the laboratory. We found that smoke and decomposition occurred when the temperature was above 380 °C, and there was no open flame even at 500 °C. This shows that it has nothing to do with the electrostatically sprayed paint powder. Therefore, an important factor that can cause brake pad burning is drag grinding.

The reasons for dragging are:

1. Inappropriate brake fluid is selected: If the "alcohol" brake fluid that is easy to be thermally expanded is wrongly selected, the brake fluid will push the brake piston after thermal expansion and cause dragging. The price of the brake tuck varies greatly, ranging from 30 yuan/liter to 300 yuan/liter. It is inevitable that the market will be confused. Disc brakes require the use of special synthetic brake fluids to reduce thermal expansion, and for rubber, metal and other brake auxiliary Corrosion damage of parts.

2. The handbrake is not completely released

Generally, it is a rear drum-type driving and parking sharing system, and a few are rear-disc sharing systems. If the handbrake is not completely relaxed, it will cause drag and abrasion during driving;

3. The floating guide rail of floating caliper brake assembly has too much resistance due to aging and other reasons. For buses, it is generally required to be below 100N. Too much sliding resistance will cause drag and wear.

4. The aging of the brake return rubber accessories will cause drag and wear

5. Brake pads are heated and expanded: under normal circumstances, as the braking progresses, the temperature rises, the linings expand, and the thickness tends to increase by △A; at the same time, the thickness decreases by △B due to wear during the braking process; if △A-△B> 0, it is dilated. Since △A is much larger than △B in the short-term braking process, △A is mainly considered. Thermal expansion is a common phenomenon of friction materials. Only when the thermal expansion exceeds the standard can cause drag and wear hazards.

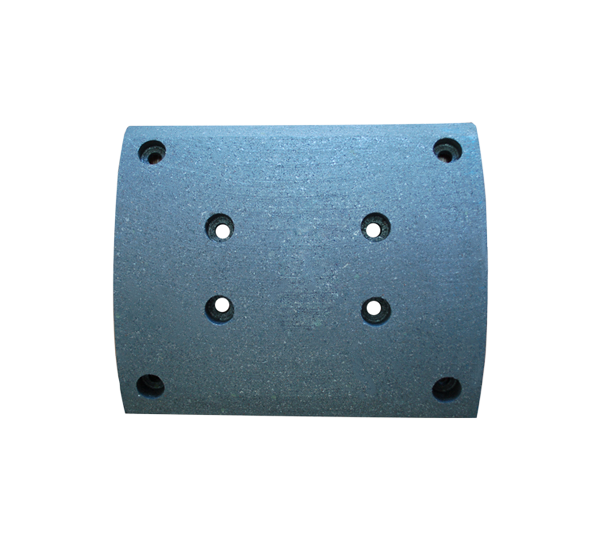

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

English

English 中文简体

中文简体