The braking system achieves the braking effect by generating friction between the brake pads and the drum or disc. The current mainstream family car brakes are composed of brake pads and brake discs. So what exactly do these two things do? Next, Che Yi'an will briefly talk about it for everyone.

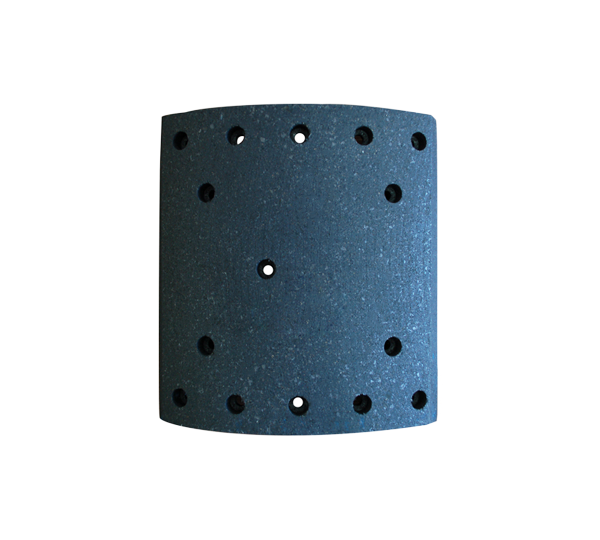

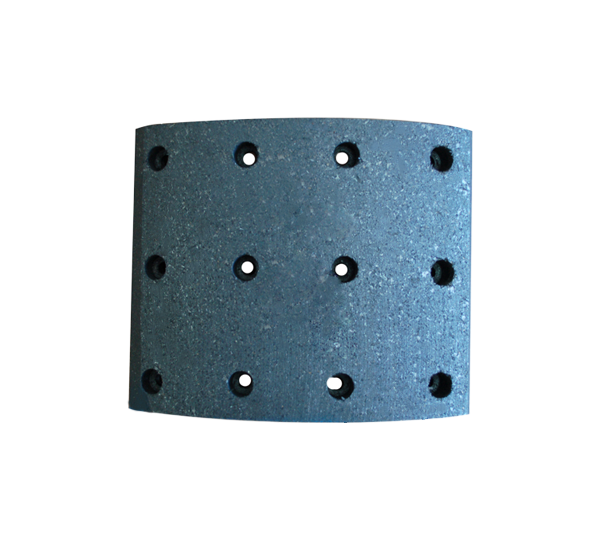

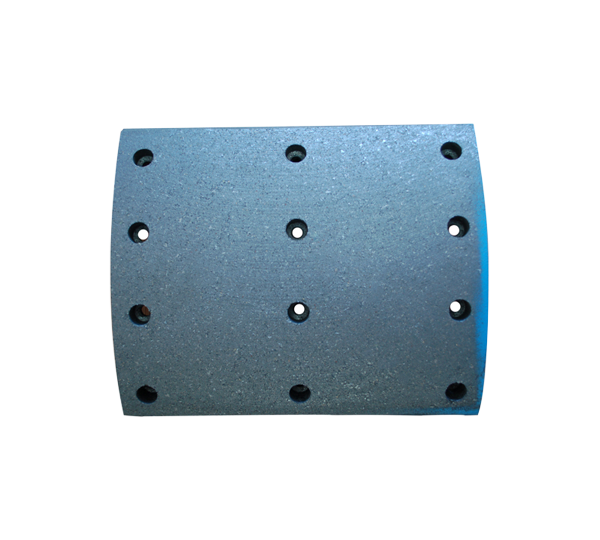

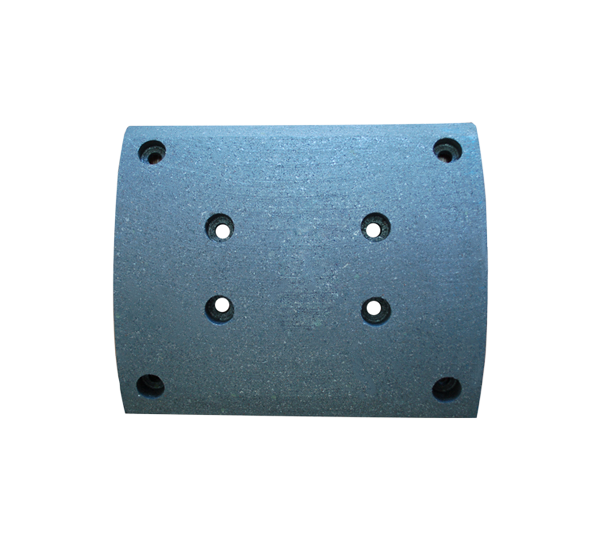

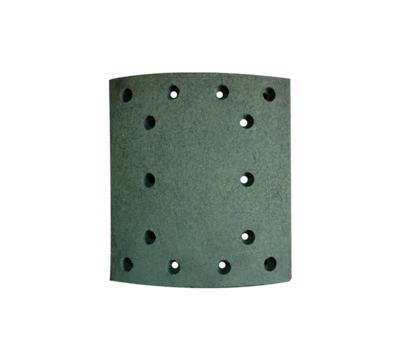

Brake pads:

Generally, it is composed of steel plate, adhesive insulation layer and friction block. The insulation layer is composed of non-heat-conducting materials for the purpose of heat insulation (if it is overheated, it is easy to cause the brake system to burn out). The friction block is composed of friction materials and adhesives. When braking, it is squeezed on the brake disc or brake drum to generate friction, so as to achieve the purpose of decelerating and braking the vehicle. Due to friction, the friction pads are gradually worn away.

Brake disc:

Simply put, it is a round plate that rotates when the car is moving. The brake caliper (the brake pad friction block mentioned above) clamps the brake disc to generate braking force. When the brake is applied, it clamps the brake disc to slow down or stop.

What is the difference between brake pads and brake discs? Everyone knows the braking principle of a bicycle. As long as you squeeze the brake with your hand, the two brake leathers clamp the bicycle wheel, so as to achieve the purpose of bicycle braking. Similarly, the braking system of a car is relatively complicated, but the principle is the same. When you are driving, the action of stepping on the brake with your foot is equivalent to the bicycle hand pressing the brake. Therefore, the brake shoes of the car drive the brake pads, so that the rotating brake discs generate frictional force to achieve the braking effect. Therefore, the simplest difference between them is that the brake disc is rotating like the wheel, but the brake pad is always stationary.

Their functions have been introduced, so since both components use friction braking, there will be losses. If it is damaged, it must be used to a certain extent and needs to be replaced. Generally speaking, the brake pads are divided into front brakes and rear brakes, and the replacement depends on the inspection results. Brake pads are generally checked every 5,000 kilometers. If it is found that the friction block wear is less than 1 mm, it needs to be replaced. (Generally, the brake pads should be replaced every 30,000 to 40,000 kilometers)

The replacement cycle of the brake disc can be determined according to the number of replacements of the brake pads. Usually, the brake disc needs to be replaced every 2 times the brake pads are replaced. But it is still more dependent on the inspection results. (Generally speaking, the brake disc is replaced once every 60,000-80,000 kilometers)

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

Founded in 1986,Hangzhou Jiuding Auto Spare Parts Co., LTD. located in Xiaoshan, Zhejiang Province, is the governing unit of China friction seal material association. As China Wholesale Non Asbestos Brake Linings Manufacturers and OEM asbestos free brake pads Factory, we specialize in the production of various kinds of brake linings and brake padsthe company has a perfect testing equipment, the stability of the production technology and strict quality control system, conforming to the requirements of the national authoritative organization detect. In 2007,the company passed ISO/TS16949 international quality management system certification, and passed the FMVSS 121 (USA), SEAJ661(USA) SABS certification (South Africa). We supply Non Asbestos Brake Pad Replacement Wholesale and has been well received by domestic and international users for its comprehensive cost performance. We are willing to work together with our friends to create a better tomorrow.

English

English 中文简体

中文简体